Metal Flap Disc On Wood . You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. Proper grinding angle and surface. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). It is important to use flap discs at the correct angle and on the correct surface. When using a flap disc on wood, you should also utilize an angle grinder's baffle. Using the incorrect angle or surface can cause epoxy wear,. The flap discs made of wood and metal are essentially the same. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. When grinding wood, why go with flap discs? For wood, you can use a flap disc.

from www.alibaba.com

Proper grinding angle and surface. When using a flap disc on wood, you should also utilize an angle grinder's baffle. It is important to use flap discs at the correct angle and on the correct surface. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. Using the incorrect angle or surface can cause epoxy wear,. The flap discs made of wood and metal are essentially the same. For wood, you can use a flap disc. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. When grinding wood, why go with flap discs?

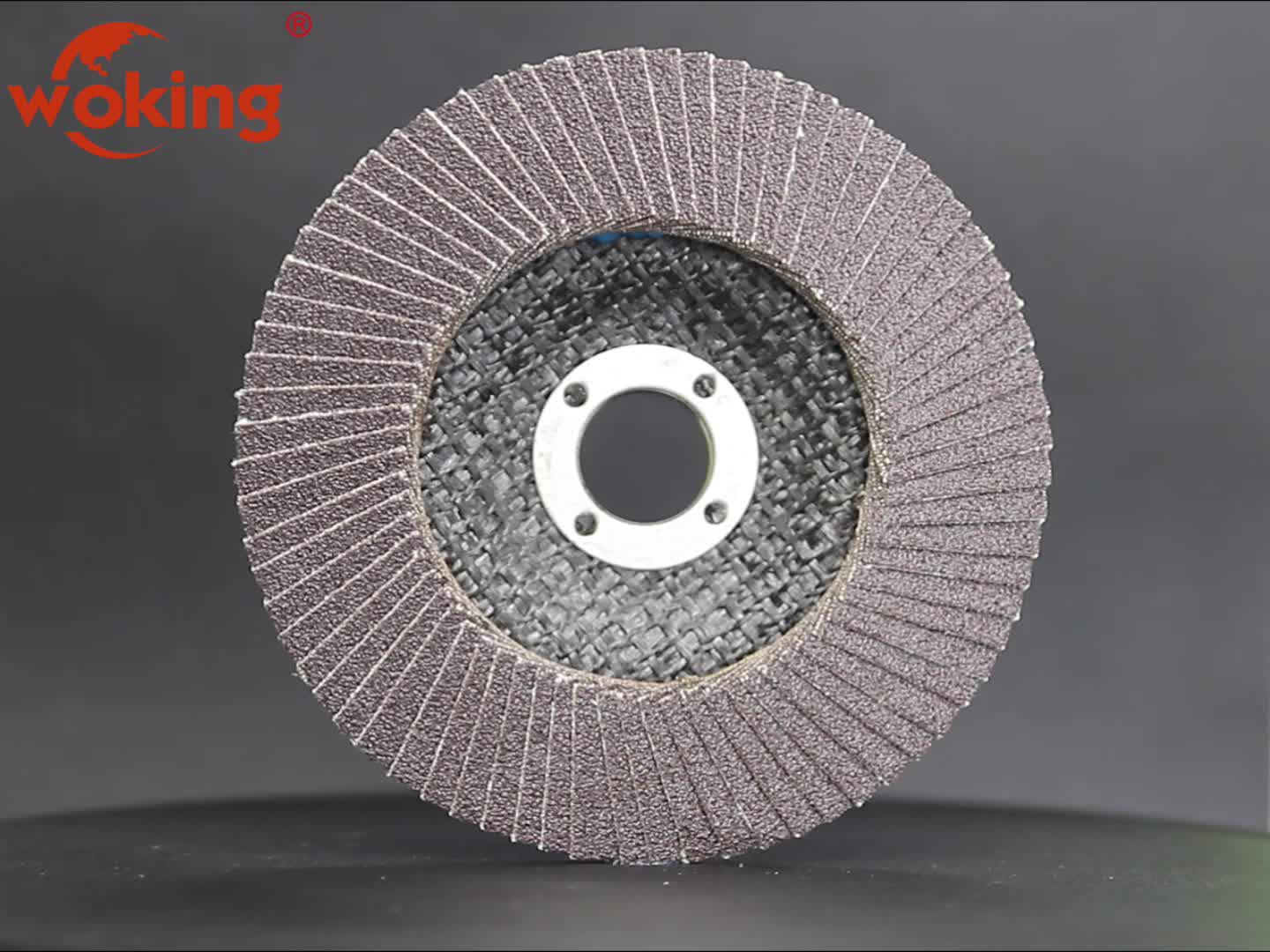

125 Mm With Fiberglass Backing Flap Disc For Wood Or Steel Buy 125 Mm

Metal Flap Disc On Wood For wood, you can use a flap disc. Using the incorrect angle or surface can cause epoxy wear,. Proper grinding angle and surface. It is important to use flap discs at the correct angle and on the correct surface. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). The flap discs made of wood and metal are essentially the same. For wood, you can use a flap disc. When using a flap disc on wood, you should also utilize an angle grinder's baffle. When grinding wood, why go with flap discs?

From ultrashineindia.com

Vertical Flap Disc Ultrashine (India) Metal Flap Disc On Wood Proper grinding angle and surface. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. When using a flap disc on wood, you should also utilize an angle grinder's baffle. The flap discs made of wood and metal are essentially the same. When grinding wood,. Metal Flap Disc On Wood.

From www.hss-drillbits.com

Abrasive Flap Disc Aluminium Oxide For Metal Stainless Steel Assorted Pack Metal Flap Disc On Wood Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. It is important to use flap discs at the correct angle and on the correct surface. When grinding wood, why go with flap discs? When using a flap disc on wood, you should also utilize. Metal Flap Disc On Wood.

From www.aliexpress.com

10PCS Grit 80 Flap Discs 4"Grinding Wheels Angle Grinder Sanding Discs Metal Flap Disc On Wood Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. When using a flap disc on wood, you should also utilize an. Metal Flap Disc On Wood.

From www.exchangeablade.com

Abrasives Wood & Metal Flap Disc Type 29 Stay Sharp® EAB Tool Company Metal Flap Disc On Wood Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. For wood, you can use a flap disc. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). The flap discs made of wood and metal are essentially the same. When. Metal Flap Disc On Wood.

From www.aliexpress.com

115mm/4.5" Flap Discs Wheels Grinding Sanding Discs 40/60/80/120 Grit Metal Flap Disc On Wood Using the incorrect angle or surface can cause epoxy wear,. The flap discs made of wood and metal are essentially the same. Proper grinding angle and surface. When using a flap disc on wood, you should also utilize an angle grinder's baffle. When grinding wood, why go with flap discs? Flap discs for metal are the ideal choice for multiple. Metal Flap Disc On Wood.

From www.cgwabrasives.com

A3 Flap Discs Flap Discs CGW Abrasives Metal Flap Disc On Wood Using the incorrect angle or surface can cause epoxy wear,. The flap discs made of wood and metal are essentially the same. When using a flap disc on wood, you should also utilize an angle grinder's baffle. Proper grinding angle and surface. You’ll also want to select the appropriate grit size based on the type of grinding and decide between. Metal Flap Disc On Wood.

From tasweld.com.au

TasWeld 3M 769F Flap Disc 125mm x 22.23mm 40G Metal Flap Disc On Wood Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). Proper grinding angle and surface. The flap discs made of wood and metal are essentially the same. Using the incorrect angle or surface can cause epoxy wear,. It is important to use flap discs at the correct angle and on the correct surface. When using a. Metal Flap Disc On Wood.

From www.exactdesigns.co.in

5 PC 41/2"x7/8" 100 Grit Blue Zirconia Flap Disc Angle Grinder Sanding Metal Flap Disc On Wood When grinding wood, why go with flap discs? When using a flap disc on wood, you should also utilize an angle grinder's baffle. Proper grinding angle and surface. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and. Metal Flap Disc On Wood.

From www.pinterest.com

Flap discs are a versatile product that can be used from aggressive Metal Flap Disc On Wood For wood, you can use a flap disc. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. Proper grinding angle and surface. Using the incorrect angle or surface can cause epoxy wear,. When grinding wood,. Metal Flap Disc On Wood.

From www.alibaba.com

Flexible Abrasive Flap Discs For Stainless Steel Sanding Buy Flap Metal Flap Disc On Wood It is important to use flap discs at the correct angle and on the correct surface. When grinding wood, why go with flap discs? Proper grinding angle and surface. When using a flap disc on wood, you should also utilize an angle grinder's baffle. Using the incorrect angle or surface can cause epoxy wear,. Flap discs for metal are the. Metal Flap Disc On Wood.

From www.amazon.com

Flap Disc, 4 1/2 In x 80 Grit, 5/811 Abrasive Flap Discs Metal Flap Disc On Wood When grinding wood, why go with flap discs? It is important to use flap discs at the correct angle and on the correct surface. Proper grinding angle and surface. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). When using a flap disc on wood, you should also utilize an angle grinder's baffle. The flap. Metal Flap Disc On Wood.

From amtechdiy.com

115mm flap disc (40 grit) Amtech Metal Flap Disc On Wood It is important to use flap discs at the correct angle and on the correct surface. Proper grinding angle and surface. Using the incorrect angle or surface can cause epoxy wear,. For wood, you can use a flap disc. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing. Metal Flap Disc On Wood.

From www.exchangeablade.com

Abrasives Wood & Metal Flap Disc Type 29 Stay Sharp® EAB Tool Company Metal Flap Disc On Wood For wood, you can use a flap disc. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and surface shape. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock. Metal Flap Disc On Wood.

From blueshark-cutting-and-grinding-discs.blogspot.com

Blueshark Abrasives CO.,Ltd Aluminum Flap Discs Metal Flap Disc On Wood It is important to use flap discs at the correct angle and on the correct surface. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. Choose a flap disc compatible with the material of your workpiece (e.g., metal, wood). You’ll also want to select. Metal Flap Disc On Wood.

From www.alibaba.com

125 Mm With Fiberglass Backing Flap Disc For Wood Or Steel Buy 125 Mm Metal Flap Disc On Wood Proper grinding angle and surface. It is important to use flap discs at the correct angle and on the correct surface. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. For wood, you can use a flap disc. When grinding wood, why go with. Metal Flap Disc On Wood.

From www.homedepot.com

DIABLO 41/2 in. 40Grit Steel Demon Grinding and Polishing Flap Disc Metal Flap Disc On Wood When using a flap disc on wood, you should also utilize an angle grinder's baffle. For wood, you can use a flap disc. Proper grinding angle and surface. It is important to use flap discs at the correct angle and on the correct surface. Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication,. Metal Flap Disc On Wood.

From bax.tools

TOTAL FLAP DISC 115mm P60 (TAC631152) Metal Flap Disc On Wood Proper grinding angle and surface. For wood, you can use a flap disc. When using a flap disc on wood, you should also utilize an angle grinder's baffle. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based on your grinding angle and. Metal Flap Disc On Wood.

From gxpgft.en.made-in-china.com

4& Soft and Flexible Flap Disc for Wood, Plastic, Aluminum and Metal Flap Disc On Wood Flap discs for metal are the ideal choice for multiple stages and processes within metal fabrication, from stock removal to smoothing out surface imperfections and. For wood, you can use a flap disc. You’ll also want to select the appropriate grit size based on the type of grinding and decide between flat (type 27) or conical (type 29) discs based. Metal Flap Disc On Wood.